In summer, photovoltaic power plants are affected by severe weather such as high temperature, lightning and heavy rain. How to improve the stability of photovoltaic power plants from the perspective of inverter design, overall power plant design and construction?

01

Hot weather

—

This year, the El Niño phenomenon may occur, or the hottest summer in history will usher in, which will bring more severe challenges to photovoltaic power plants.

1.1 The effect of high temperature on components

Excessive temperature will reduce the performance and life of components, such as inductors, electrolytic capacitors, power modules, etc.

Inductance: At high temperature, the inductance is easy to be saturated, and the saturated inductance will decrease, resulting in an increase in the peak value of the operating current, and damage to the power device due to over-current.

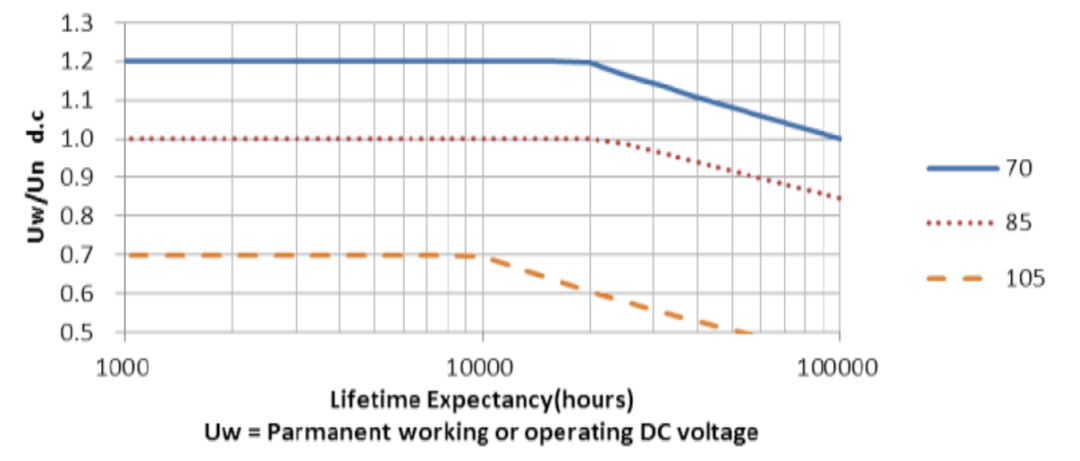

Capacitor: For electrolytic capacitors, the life expectancy of electrolytic capacitors is reduced by half when the ambient temperature rises by 10°C. Aluminum electrolytic capacitors generally use a temperature range of -25~+105°C, and film capacitors generally use a temperature range of -40~+105°C. Therefore, small inverters often use film capacitors to improve the adaptability of inverters to high temperatures.

The life of capacitors at different temperatures

Power module: The higher the temperature, the higher the junction temperature of the chip when the power module is working, which makes the module bear high thermal stress and greatly shorten the service life. Once the temperature exceeds the junction temperature limit, it will cause thermal breakdown of the module.

1.2 Inverter Heat Dissipation Measures

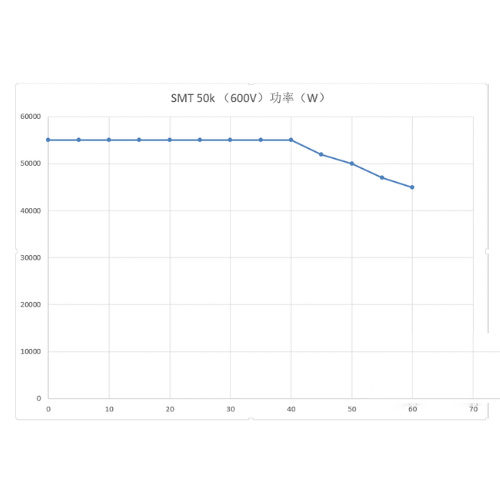

The inverter may operate outdoors at 45°C or higher temperature. The heat dissipation design of the inverter is an important means to ensure the stable, safe and reliable operation of each electronic component in the product within the working temperature. The temperature concentration point of the inverter is the boost inductor, inverter inductor, and IGBT module, and the heat is dissipated through the external fan and the back heat sink. The following is the temperature derating curve of GW50KS-MT:

Inverter temperature rise and fall load curve

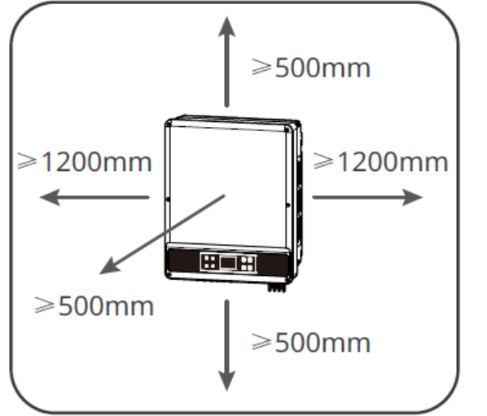

1.3 Construction anti-high temperature strategy

On industrial roofs, the temperature is often higher than that on the ground. In order to prevent the inverter from being exposed to direct sunlight, the inverter is generally installed in a shady place or a baffle is added on the top of the inverter. It should be noted that the space for operation and maintenance should be reserved at the position where the inverter fan enters and exits the wind and the external fan. The following is an inverter with left and right air intake and exit. It is necessary to reserve sufficient space on both sides of the inverter, and reserve an appropriate distance between the sun visor and the top of the inverter.

02

Thunderstorm weather

—

Thunderstorms and rainstorms in summer.

2.1 Inverter Lightning and Rain Protection Measures

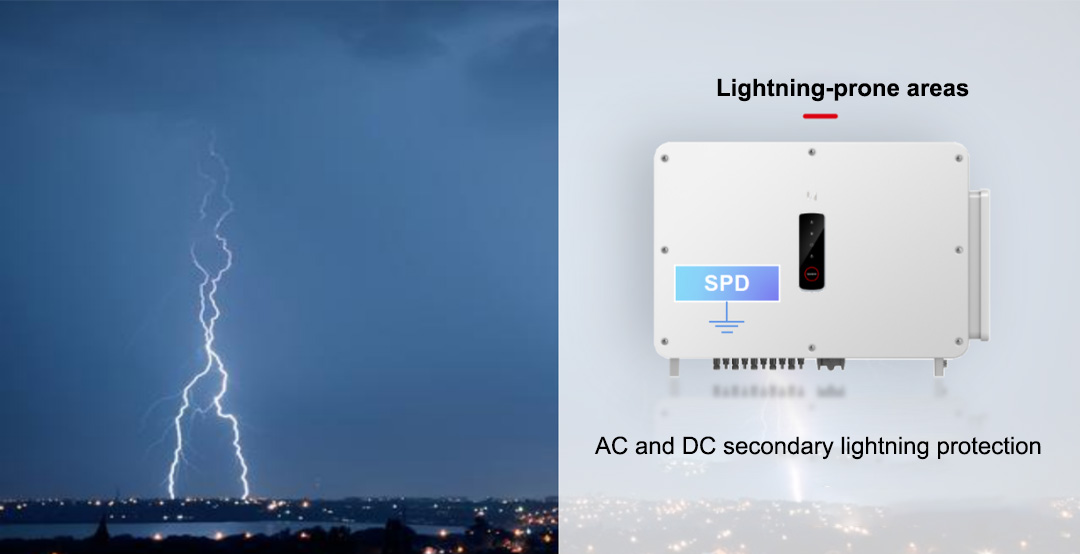

Inverter lightning protection measures: The AC and DC sides of the inverter are equipped with high-level lightning protection devices, and the dry contacts have lightning protection alarm uploads, which is convenient for the background to know the specific situation of lightning protection.

Inverter rain-proof and anti-corrosion measures: The inverter adopts a higher IP66 protection level and C4&C5 anti-corrosion level to ensure that the inverter continues to work under heavy rain.

False connection of the photovoltaic connector, water ingress after the cable is damaged, resulting in a short circuit on the DC side or ground leakage, causing the inverter to stop. Therefore, the DC arc detection function of the inverter is also very important.

2.2 Overall lightning protection (construction) strategy

Do a good job of the earthing system, including component terminals and inverters.

Lightning protection measures on the solar panel and inverter

Rainy summers can also cause weeds to grow and shade components. When the rainwater washes the components, it is easy to cause dust accumulation on the edges of the components, which will affect the subsequent cleaning work.

Do a good job in system inspection, regularly check the insulation and waterproof conditions of photovoltaic connectors and cables, observe whether the cables are partially soaked in rainwater, and whether there are aging and cracks in the cable insulation sheath.

Photovoltaic power generation is all-weather power generation. The high temperature and thunderstorms in summer have brought severe challenges to the operation and maintenance of photovoltaic power plants. Combining the inverter and the overall power plant design, Xiaogu gives suggestions on construction, operation and maintenance, and hopes to be helpful to everyone.

Post time: Jul-21-2023